Sand and gravel production site

Sand and gravel are produced by the decomposition of resistant minerals such as quartz. Sand is used to prepare various types of cement mortar, concrete, sand-lime bricks, etc. In the construction industry, grains with a diameter of 2 to 0.06 mm are called sand.

Sand is divided into several categories depending on its source. Double-broke broken sand is obtained artificially and from crushing dense rocks such as granite. Broken sand grains are sharp-edged and have very rough surfaces. Therefore, it is suitable for making concrete. The meaning of 04 and 06 sand is that the largest diameter of the aggregate does not exceed 4 mm and 6 mm, respectively.

Single-broke sand or filler is mainly used for making mortar. Double-broke sand is used in making concrete due to less soil.

Sand is also used in the manufacture of special mortars. Below is a list of materials that can be produced.

Contact us for additional information and advice on ordering batching types.

Sand and gravel production site

Sand and gravel are produced by the decomposition of resistant minerals such as quartz. Sand is used to prepare various types of cement mortar, concrete, sand-lime bricks, etc. In the construction industry, grains with a diameter of 2 to 0.06 mm are called sand.

Sand is divided into several categories depending on its source. Twice-salted broken sand is obtained artificially and from crushing dense rocks such as granite. Broken sand grains are sharp-edged and have very rough surfaces. Therefore, it is suitable for making concrete. * The meaning of sand 04 and 06 is that the largest diameter of the aggregate does not exceed 4 mm and 6 mm, respectively.

Single-salted sand or filler is mainly used for making mortar. Twice-salted sand is used in making concrete due to less soil.

Sand and gravel is also used in the manufacture of special mortars. The list of materials that can be produced is presented below.

Components of a sand and gravel production site:

Grizzly screen: Grizzly screen produced by Metal Sanat Industries is one of the equipment for transferring materials and materials to the jaw opening or conveyor belt. This device has the operation of separating coarse aggregates from soil and fine grains. Grizzly screens are produced in different sizes and types according to the type of granulation and customer materials.

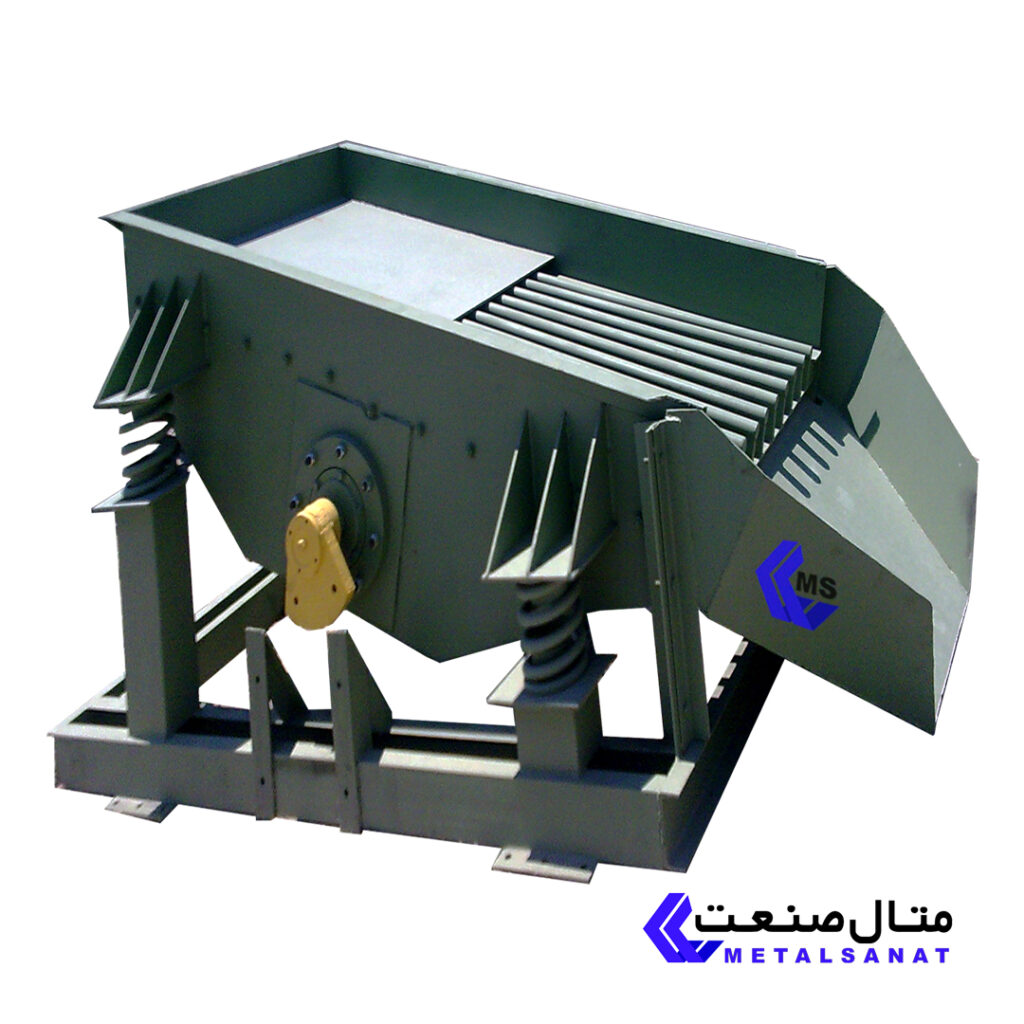

Vibrating screen: One of the equipment used in mines and various industries is the vibrating screen of Metal Sanat Industries, which is used for granulation and separation of materials. The screen device is used to separate soil from sand and gravel or granulate sand in different sizes.

Cubit crusher: HS series Cubit crusher of Metal Sanat Industries is a Cubit crusher that is used for crushing hard rocks. The anvils of the machine are installed in three series, each of which can be adjusted and regulated separately so that the required product can be obtained in different sizes.

Jaw crusher: The jaw crusher of Metal Sanat Industries is the first device installed in the crushing production line and is generally used to crush very large rocks into smaller sizes.

Cone crusher: The hydrocone or cone crusher of Metal Sanat Industries is a type of crusher that is one of the important tools for crushing and breaking rocks and minerals, and these tools are also used in many industries.

Grizzly feeder: The responsibility of the grizzly feeder of Metal Sanat Industries is to direct the load to the jaw opening or screen, which benefits from the issue of directing the load regularly to the jaw opening or the mother conveyor belt. In essence, this device is the beating heart of mining machinery and the work begins with this device.

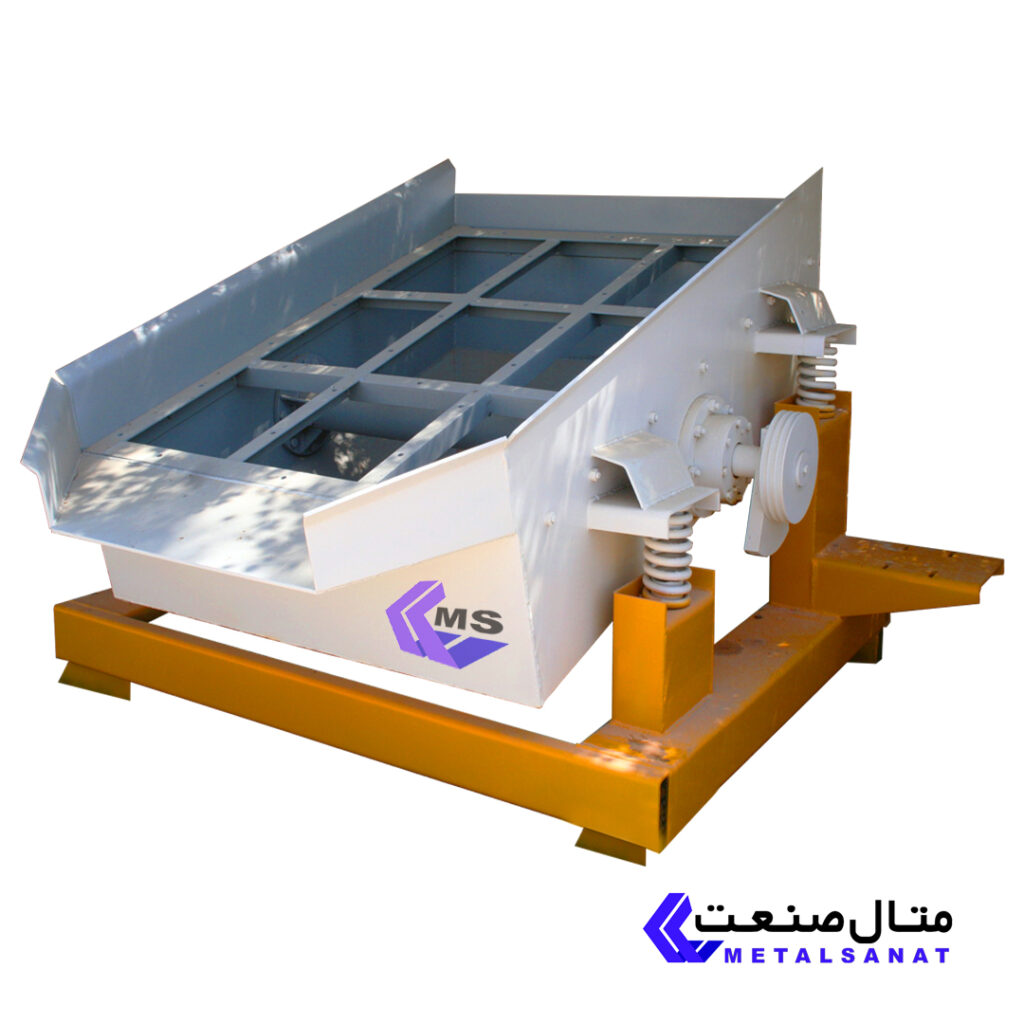

Vibrating Feeder: Metal Industry Industries' vibrating feeders are located at the beginning of the crushing lines and are designed and manufactured for use in harsh conditions and long and continuous operation in primary crushing operations. This device is designed and manufactured in such a way that the load is guided regularly and with a load adjustment capacity and with the help of an adjustable outlet valve, it performs mechanical load guidance operations and is installed and commissioned in various types and tonnages in mineral facility lines.

Sand-sand spiral: Metal Industry Industries' sand-sand spiral is one of the equipments that is suitable for washing sand with a fine grain size of 0 to 6 mm or pea and almond materials in sand and sand mines. The sand-sand spiral is used for separating and washing the product in crushing and processing facilities for minerals and sand and sand and is usually installed below the first screen. This device operates in a spiral manner and separates impurities from the material through a specific process.

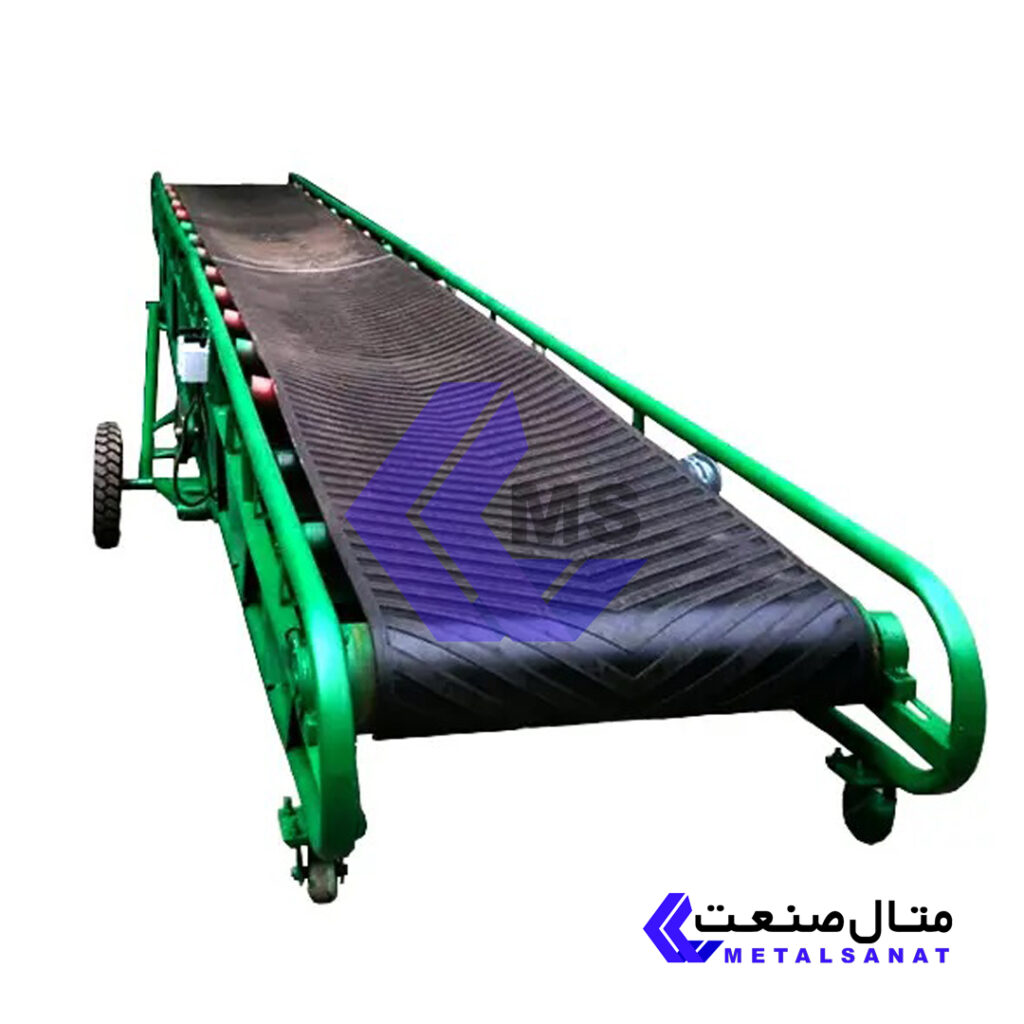

Mineral material conveyor belt: One of the equipment for transporting materials or moving mineral materials in small mines and various industries is the Metal Industry conveyor belt, which is very widely used, and in fact, without this equipment, it is not possible to start, operate, and move materials and materials. It provides the ability to transport a very high volume of materials at a very suitable speed. Conveyor belts are used in many industries as a standard piece of mechanical handling equipment to move goods, products, raw materials, and other materials from one place to another.

بدون دیدگاه